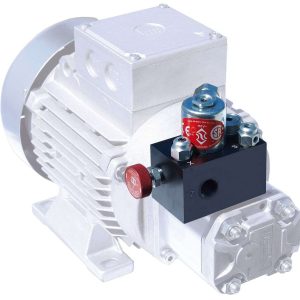

L 10 Description: L10 Description: The L10 Pressure Lock Valve is a solenoid operated check valve designed for hydraulic elevators and includes a self closing manual lowering valve. Its purpose is to allow free fl ow of oil from the pump unit A to the cylinder B for upward travel and to prevent fl ow in the reverse direction from B to A until an electrical signal is given to the solenoid.

Installed in the main cylinder line directly adjacent to the main elevator control valve, the L10 can be employed as a safety back up valve to the down system of the main control valve to prevent unwanted down movement of the elevator should an electrical or mechanical malfunction occur in the main control valve.

Another application of the L10 is to reduce the amount of bounce in a hydraulic elevator system due to the compressability factor of oil between the cylinder and the control valve, by mounting the L10 directly onto the cylinder connection. A Slack Rope Valve LK for roped elevators (e.g. 2:1 indirect transmission) is optional. It prevents the slack rope condition caused by the lowering of the ram when the car is suspended in the safeties or resting on the buffer.

| Technical Data: | P-Z | ½” L10 |

¾” L10 |

1½” L10 |

2″ L10 |

2½” L10 |

| Flow Range max.: | lpm | 80 | 125 | 400 | 800 | 1400 |

| Operating Pressure min/max: | bar | 0-100 | 10-100 | 10-59 | 12-59 | 12-59 |

| Burst Pressure: | bar | 500 | 500 | 500 | 450 | 360 |

| Tank Connection for LH: | T | 1/4″ | 1/4″ | 1/2″ | 1/2″ | 1/2″ |

| Weight: | kg | 0.8 | 1.4 | 2.5 | 4.2 | 7.0 |

| PB Cylinder pressure port: | G 1/4″ |

Reviews

There are no reviews yet.